![]()

ONLINE

Glass Masters

Editors’ Note

Jeffrey Brenner’s family has owned a gift, luggage, leather goods, and shoe repair business in Montgomery, Alabama since 1910. He learned about small business and the retail industry at the side of his father in his family’s store. His formal training took place with retail giants Macy’s, Neiman Marcus, and Saks Fifth Avenue, to include such iconic brands as Hartmann Luggage and Steuben Glass. Brenner joined Pelucida Glass in the fall of 2013 in his current post. He attended the University of Alabama, School of Communications and Business.

Company Brief

Pelucida (www.pelucidaglass.com) is a state-of-the-art architectural and special commission glass manufacturing studio based in the Finger Lakes region of Upstate New York. Pelucida combines technical and design expertise with decades of work at the highest levels of the glass manufacturing industry. While creating some of the most memorable special commissions produced over the past quarter century, the company’s principals were a part of Steuben Glass for many years and contributed significantly to the rich tradition of that iconic American brand. The company’s focus is in the areas of major commissioned works, architectural elements, custom awards, and trophies.

How will the company be positioned in the market?

We will provide to both the corporate and consumer communities the opportunity to design and develop commissioned pieces used for recognition for special projects, deal closings, capital development, and architectural designs all manufactured out of glass. The pieces are produced in the U.S. at our factory using both new and established designers from across the U.S.

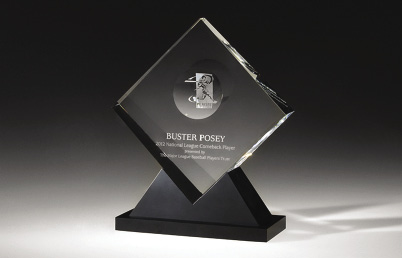

Major League Baseball Players Choice Award

How do you develop commissioned and special pieces?

One thing we’re not is cookie-cutter. We encourage our customers to give us their visions and needs, and we will interpret these by designing and developing multiple concepts for them to consider.

We position ourselves quite well against the mass production award companies and the high-end luxury glass companies in the industry, because each of our items will be unique. We allow the customer to work with us in making the decision on what they want versus telling them what we have for them to choose from.

What might be a typical production run for a design?

When we talk about a single item, it may be an iconic piece to recognize a specific milestone or a corporate initiative. It could be a much larger piece going into the lobby of an office building.

Otherwise, it depends on the need. Someone may need 100 pieces to recognize a program or project, and we can do that. There is no limit on the number of units.

However, we don’t do a bunch of basic shapes that sit on a shelf that we look at as being mass market. Many of those products are being bought from overseas, whereas we want to develop and manufacture in the U.S.

Malcolm Baldrige National Quality Award

How do you intend to build brand awareness, and is your market niche or is it broader?

It depends on the industry and the market. We’re very focused on corporations in industries, such as agencies, PR and marketing, finance, real estate, manufacturing, and technology that have strong growth potential and are looking to do things to recognize certain initiatives.

We have a number of projects that were recently awarded. We were given a multiyear contract to produce the Malcolm Baldrige National Quality Award, which is the nation’s highest Presidential honor for performance excellence through innovation, improvement, and visionary leadership.

We were also awarded a multiyear contract for Major League Baseball’s Players Choice Award.

Additionally, we were awarded some of the trophies through NASCAR and Grand Am for specific races to include elements of the Rolex 24 series races.

This shows the depth of industries we’re going after.

What types of architectural work have you done?

We have multiple projects, one in the Southeast and one in the Midwest, where we have created glass spindles for staircases in residential homes. We also continue to design and develop fireplace surrounds where beautiful glass panels are used.

We have also done multiple furniture pieces for corporate board rooms and private residences, such as tables with glass inlays and beautiful glass etchings that have gone in boardroom doors. International projects include a personal sculpture for one of the Saudi Princes.

World Golf Hall of Fame Installation

How critical is the Made in America component in building your brand?

This touches on the Owner and President of the company, Ryan Simmons. He spent over 25 years with Steuben Glass. He fell in love with the craft of glass fabrication and machining. This is a delicate art and it takes a lifetime to master; Ryan is one of the relatively few people in the U.S. who can claim this mastery.

There still are several people who do detailed glass machining and design work, and many of them happen to be on the East Coast, especially in Upstate New York. We take advantage of the technical experts who reside in the U.S. as established and highly regarded glass artisans and designers, and up-and-coming ones as well.

Do you generally work on multiple pieces or do you focus only on one at a time?

It depends on the scope and scale of an individual project. The wonderful thing about manufacturing in our building is that we can scale, so if we need more hands to do more production, we have the facilities and flexibility for that. Some projects have a much longer lead time, but once the design is in place, it becomes a technical exercise, and we can start to concentrate on other projects.

What are the things you do to build the brand?

I’ll utilize my vast network of professional and personal contacts, backed by my passion for quality product and its application to a specific need, to expand the awareness of our brand for both corporations and individuals. I’m fascinated by how a given piece can drive a certain emotion. What excites me most is this organization of people who are so talented, open to being creative, and provide a superior product that we can all be as proud of as the actual recipient.

It’s also an extremely entrepreneurial opportunity. There is no situation where our expertise doesn’t apply and that we can’t touch, from charitable organizations to design firms to everything in between.

Do you see opportunities for brand extensions?

We’re going to stick to our core competencies, and where we feel strongest. The only diversion is that we have been asked by others to potentially do some manufacturing of their products or specific pieces for them since they like that we are based in the U.S., and everything we produce is done here.•