- Home

- Media Kit

- MediaJet

- Current Issue

- Past Issues

- Ad Specs-Submission

- Reprints (PDF)

- Photo Specifications (PDF)

- Contact Us

- PRIVACY POLICY

- TERMS OF USE

![]()

ONLINE

![]()

ONLINE

Advancing Solar Energy

Editors’ Note

Li You is a leading executive in the solar industry and investor in state-of-the-art solar and photovoltaic technologies. His new U.S. company, EKL Solar, is deploying significant capital and incorporating leading-edge solar manufacturing technology to build a U.S.-based R&D center and manufacturing plant serving U.S. solar companies as well as international markets. In addition to directing overall investment and growth, Li leads the company’s strategy and international expansion.

Company Brief

EKL Solar is a U.S.-based company engaged in advanced manufacturing technology for solar energy modules, increasing the efficiency and lowering the cost of solar energy. It is investing $200 million in research and manufacturing in the U.S. based on its cutting-edge proprietary technology. While the technology was developed in China, EKL invests in and serves XX international markets in the Americas, Asia, Africa and Europe.

EKL is in the process of establishing a

U.S. solar panel production facility

What is the competitive advantage of your team and company that drives market leadership outside the U.S.?

We manufacture machines that optimize the process of building solar modules, which are complete, encapsulated units ready for installation as opposed to individual solar panels. Within only three years, we have developed a novel manufacturing process that can more quickly and cost effectively produce solar modules. We sell into major international markets including Europe, Africa, North America, and Asia. A typical order from a solar energy company is five machines per solar module production line with a capacity of 2 GW. Under this industrial arrangement, each line can save the customer roughly $960,000 per year. There was one U.S. client that purchased 20 pieces of our newest machines and saved almost $3.84 million in manufacturing costs this year.

What other benefits are there for your customers in addition to cost savings?

Our international company is already profitable. We constantly invest a significant portion of our profits into research and development to further improve our technology. The most important benefit to our customers, however, is after-sale service. When we install our equipment, our engineers embed themselves with the client to make sure our machines are completely and seamlessly integrated into their production processes. In addition, our engineers provide ongoing service support well after a sale.

Who are your customers?

We have three types of customers:

• Those that have strong sales and want cost efficiencies

• New startups with whom we work to establish initial production lines

• Companies suffering losses due to production inefficiencies

Aside from supplying new machines, we can also modernize existing equipment. An example of how we work with customers is in Algeria, where we helped not only develop a manufacturing capability for a local company, but developed a solar power plant for them as well. We have across-the-board expertise in solar energy.

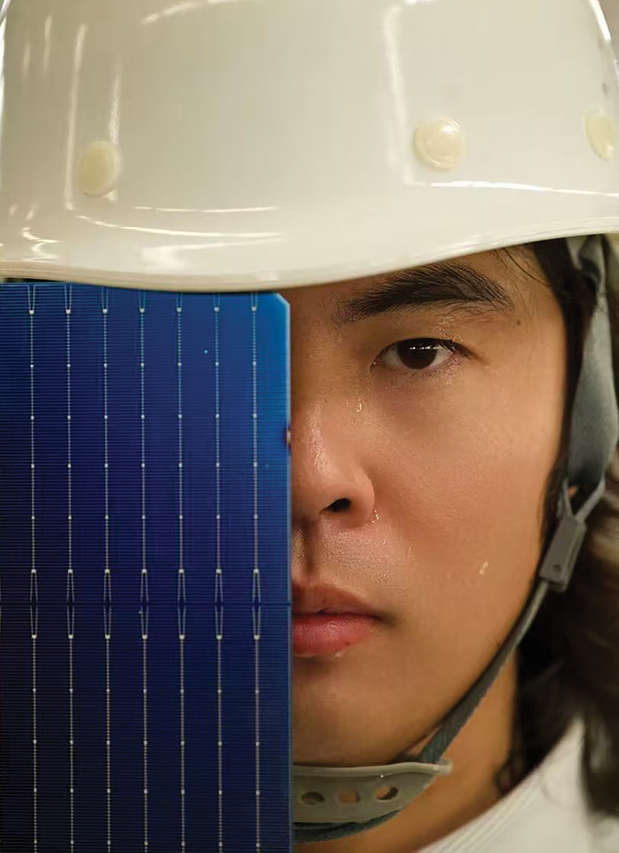

During the development of the tablet pressing technology,

every

step is meticulously controlled. The image shows

the measurement of the edge thickness of a

finished photovoltaic panel. Precision is the guiding

principle, and perfection is the goal.

Where do you plan to be located, how much are you investing, and will EKL be publicly traded?

We currently are scouting locations in the U.S. to launch operations in the next 6 to 12 months. We will be investing some $200 million in capital and expect to employ between 150 to 300 workers. While a privately held start-up company at present, eventually we intend to be listed as a publicly traded U.S. company on NASDAQ.

What do you see as the market potential in the U.S.?

We see enormous potential. The U.S. Solar Energy Industry Association notes that the solar growth rate has averaged 28 percent over the past decade, and the total market value exceeds more than $70 billion. Demand for electricity in the U.S. is increasing at historic levels, driven not only by the country’s re-industrialization policy, but also by increasing numbers of AI data centers that consume vast quantities of electricity, electric vehicles, advanced manufacturing technology such as electric arc furnaces in steel making, and increased air conditioning in a warming planet. There are more than 10,000 solar companies in the U.S. right now, forming a huge customer base.

What are the benefits for the U.S. solar industry?

The U.S. solar market is already fairly developed. We are here not to beat anyone, but to lead the whole industry with our cutting-edge technology and reduce overall costs for the line. So, there will be larger benefits coming to the U.S. from our entry into the market. It is generally acknowledged that while solar energy has been growing fast in the U.S., the growth of the industry’s capacity to actually produce solar modules has been very limited. Not only will we invest $200 million in the new R&D facility and manufacturing plant – we will also develop U.S.-based intellectual property and the relevant industrialization that can help drive American exports to international markets. As I said, we expect to employ as many as 300 scientists and workers, which in itself will contribute to the growth of the American manufacturing sector.

How do you describe your company’s mission?

I would describe it as using technology, science, and research to advance solar energy worldwide for the benefit of the environment and humanity. We currently have some 300 employees outside of the U.S., including many with scientific and engineering backgrounds, and some with master’s and doctoral degrees. This has enabled us to develop the most advanced machines in the world today, and we are getting ready to launch next-generation machines that will give us an even greater competitive edge. The company has always been dedicated to identifying the existing technological and material boundaries and overcoming them. Solving technology challenges for our customers is our strength. Machinery is only the beginning of our plan. Our EKL Solar Module Manufacturing Project will make a further contribution to the American solar industry.

What led you to become involved in the solar industry?

I have long been engaged in environmental protection and sustainable development technology investment, including seeking breakthrough technologies in the field. After long-term research into photovoltaics, I realized how solar energy can enhance global development cost-effectively while remaining profitable, so I am devoted to this industry.

How do you see the future of solar energy and EKL?

In the U.S. alone, solar energy accounted for 69 percent of all the new electric generating capacity that was added to the U.S. grid in the first three months of this year. That shows not only the strong demand for carbon-free energy, but also its cost effectiveness with its decreasing price and renewable characteristics. We believe EKL will play a leading role in helping U.S. solar companies increase their manufacturing efficiency of solar modules domestically to support America’s re-industrialization goals while simultaneously addressing the country’s surging demand for electricity. It is quite imperative, given global warming and climate change, for us to do everything possible to promote both clean energy technologies as well as innovation. We remain fully committed to that objective.![]()